In today’s high-stakes manufacturing environments—from pharmaceuticals to semiconductors—the need for pristine, controlled spaces is non-negotiable. Contamination can lead to product failure, regulatory penalties, and significant financial loss. The central solution is the cleanroom, but the method of its construction has evolved dramatically. While traditional, “stick-built” cleanrooms were once the only option, modern modular cleanrooms offer a compelling alternative built for the speed and precision of modern industry.

This guide explains the fundamental differences between these two approaches, helping procurement managers, plant engineers, and QA directors make an informed decision for their next major facility expansion (200 square meters and larger). We will explore why Dersion’s focus on large-scale modular systems provides a strategic advantage in achieving your operational and compliance goals.

What is a Cleanroom? The Foundation of Controlled Environments

A cleanroom is a highly controlled environment designed to minimize the concentration of airborne particulates, such as dust, microbes, and aerosol particles. Its purpose is to create a stable, predictable, and contaminant-free space essential for sensitive manufacturing, research, and packaging processes.

Control is achieved through several core components:

- HEPA/ULPA Filtration: High-Efficiency Particulate Air (HEPA) or Ultra-Low Particulate Air (ULPA) filters remove particles from the air to a specified efficiency.

- Airflow Control: Air pressure differentials (positive or negative pressure), specific air change rates per hour (ACPH), and laminar or turbulent airflow patterns prevent contaminant ingress and remove internally generated particles.

- Controlled Surfaces: Walls, floors, and ceilings are constructed from non-shedding, easy-to-clean materials that resist microbial growth.

- Operational Protocols: Strict procedures for gowning, entry/exit, and material transfer maintain the environment’s integrity.

Cleanrooms are classified by their cleanliness level according to standards like ISO 14644-1, which specifies the maximum allowable particle concentration per cubic meter of air.

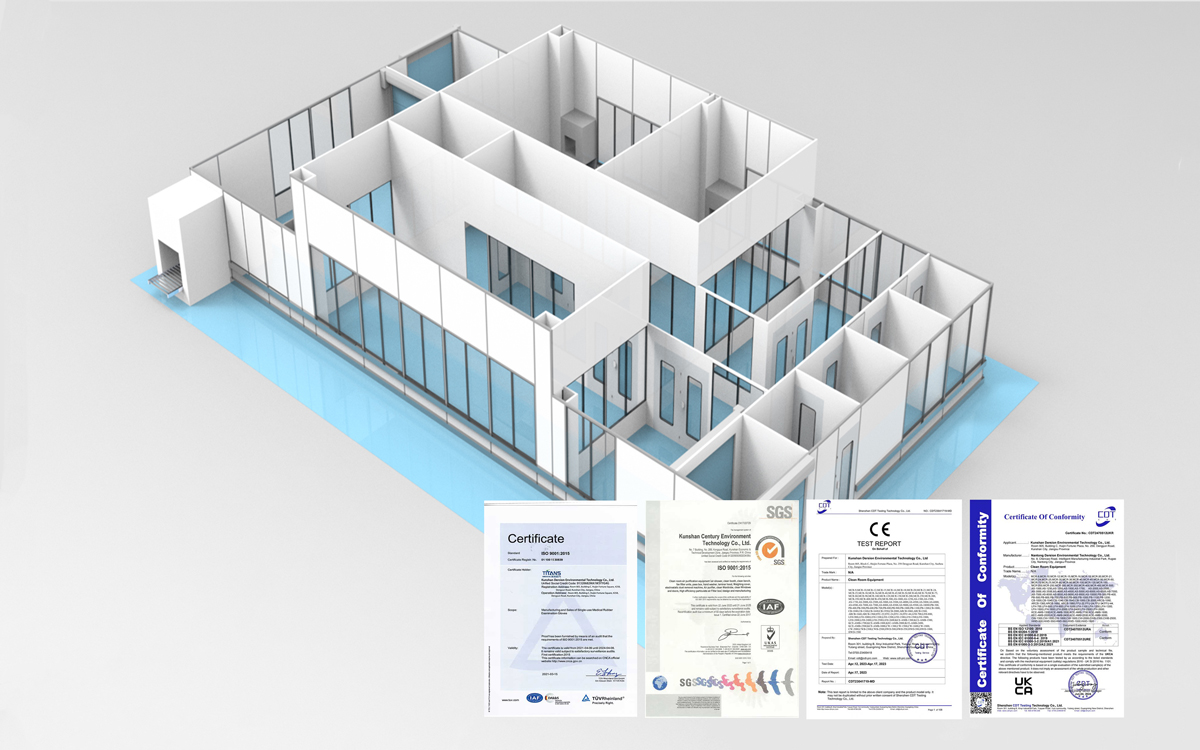

What is a Modular Cleanroom? A Modern Approach to Precision and Speed

A modular cleanroom is a controlled environment constructed using prefabricated panels and components manufactured off-site in a factory setting. These engineered systems—including walls, ceiling grids, doors, and utility chases—are then transported to the facility for rapid assembly.

Unlike traditional construction, which involves building walls stud by stud on-site, the modular approach focuses on precision engineering and minimizing on-site disruption. For large-scale projects, this means entire sections of a facility can be planned, built, and integrated with a level of speed and quality control that is difficult to achieve with conventional methods.

Key Differences at a Glance: Modular vs. Traditional Construction

| Feature | Modular Cleanroom (Dersion Approach) | Traditional (Stick-Built) Cleanroom |

| Speed | 40-60% faster project completion. Off-site manufacturing occurs parallel to on-site foundation work. | Slower, linear process. Each construction phase depends on the previous one, leading to longer timelines. |

| Cost | More predictable budget. Factory-controlled costs and reduced on-site labor mitigate cost overruns. | Prone to budget creep due to on-site delays, material waste, and trade coordination issues. |

| Flexibility | Highly adaptable. Can be reconfigured, expanded, or relocated with relative ease to meet future needs. | Permanent structure. Modifications are expensive, disruptive, and often require a complete shutdown. |

| Quality Control | Superior consistency. Panels are built to exact tolerances in a controlled factory environment. | Variable quality. Dependent on the skill of multiple on-site trades and subject to site conditions. |

| Disruption | Minimal on-site disruption, dust, and noise. Ideal for expanding existing, operational facilities. | Significant on-site construction activity, creating noise, debris, and potential contamination risks. |

| Validation | Streamlined process. Standardized components and predictable performance simplify validation and qualification. | More complex validation due to on-site material and construction variability. |

The Dersion Advantage: Engineering Excellence in Large-Scale Modular Systems (>= 200 sqm)

At Dersion, we specialize in system engineering for large-scale modular cleanrooms. Our approach is designed to de-risk major capital projects and deliver validated environments that meet the stringent demands of global leaders in life sciences, electronics, and advanced manufacturing.

Our core advantages include:

- End-to-End Project Management: We manage the entire lifecycle, from design and engineering to off-site fabrication, logistics, on-site assembly, and final validation support. This single point of contact simplifies communication and ensures accountability.

- Pre-Engineered MEP Integration: Our modular panels are designed with integrated chases and conduits for Mechanical, Electrical, and Plumbing (MEP) systems. This pre-planning ensures seamless integration of HVAC, process gases, compressed air, and electrical systems, eliminating costly on-site conflicts.

- Compliance by Design: We build compliance into every component. Our systems are engineered to meet the technical requirements of ISO 14644, EU GMP Annex 1, and FDA cGMP, ensuring your facility is audit-ready from day one.

- Scalability for the Future: Our modular architecture is built for growth. Whether you are scaling up production or adding a new BSL-rated lab, a Dersion cleanroom can expand with your business needs without requiring a complete rebuild.

Industry-Specific Benefits of Dersion Modular Cleanrooms

- Pharmaceutical & Medical Devices: Achieve rapid deployment for new drug production lines or medical device assembly, ensuring strict compliance with GMP and FDA regulations while getting products to market faster.

- Semiconductors: Create ultra-clean environments (ISO Class 3-5) with precise temperature and humidity control, protecting sensitive photolithography and wafer fabrication processes from microscopic contaminants.

- Cosmetics & Food Production: Install hygienic, easy-to-sanitize environments that meet regional food safety standards and prevent cross-contamination, ensuring product quality and consumer safety.

Navigating Global Compliance: ISO, GMP, and Regional Standards

Achieving and maintaining compliance is paramount. A Dersion cleanroom is designed to facilitate adherence to key international and regional standards:

- ISO 14644-1: The global standard for classifying air cleanliness by particle concentration.

- EU GMP Annex 1: Specific requirements for the manufacture of sterile medicinal products within the European Union.

- FDA cGMP (Current Good Manufacturing Practice): Regulations enforced by the U.S. Food and Drug Administration.

- CE Directives: Our integrated equipment and components can be specified to meet CE marking requirements for the European market.

Our team works with your QA/RA department to ensure the design, materials, and operational parameters of your cleanroom will meet the specific requirements of your target markets.

Your Project Pathway: From Concept to Validated Cleanroom with Dersion

- Consultation & Design: We partner with you to define user requirements (URS), scope, and classification needs.

- Engineering & Fabrication: Our engineers finalize designs, and fabrication begins in our state-of-the-art facility.

- Site Preparation & Assembly: While we build your modules, your site is prepared. Our specialized team then assembles the cleanroom with precision and speed.

- Commissioning & Validation Support: We commission all systems and provide comprehensive documentation (IQ/OQ/PQ support) to ensure a smooth and successful validation process.

Post time: Sep-10-2025