How to Select the Right HVAC System for a Cleanroom

Selecting the right HVAC system for a cleanroom is a critical engineering decision. The core objective is to precisely control temperature, humidity, cleanliness level, pressure differentials, and airflow patterns, while ensuring long-term stability, energy efficiency, and regulatory compliance.

A well-designed cleanroom HVAC system directly affects product quality, process reliability, and operating costs. Below are the key factors to consider when selecting a cleanroom air conditioning system.

1. Define Cleanroom Classification and Process Requirements

The first step is to determine the required cleanroom classification according to ISO 14644-1, GMP, or other applicable standards (e.g., ISO Class 5 / Class 100).

In parallel, detailed process data must be collected, including:

-

Equipment heat load

-

Moisture generation

-

Contaminant characteristics

-

Personnel density and working hours

These parameters form the basis for accurate cooling, heating, and dehumidification load calculations.

For cleanrooms with high internal heat loads (such as semiconductor, electronics, or pharmaceutical manufacturing), water-cooled HVAC systems are often preferred due to their higher energy efficiency and stable heat dissipation performance.

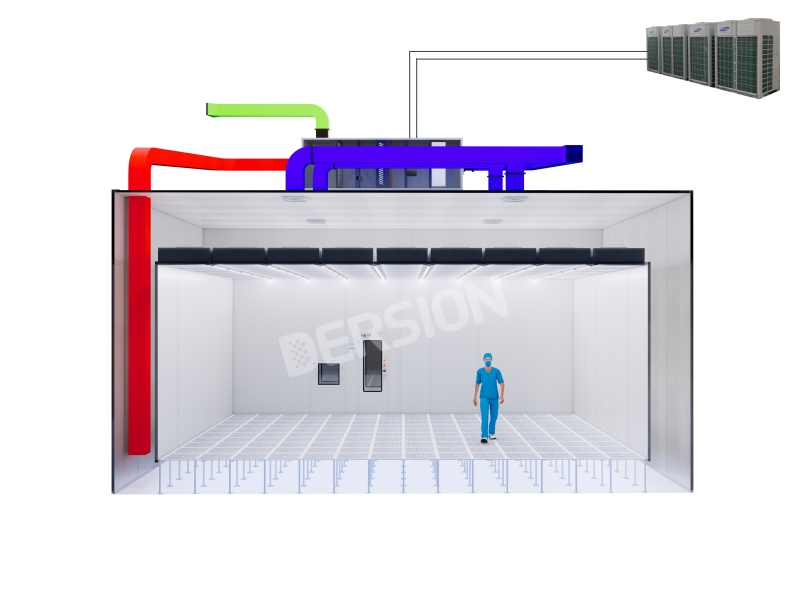

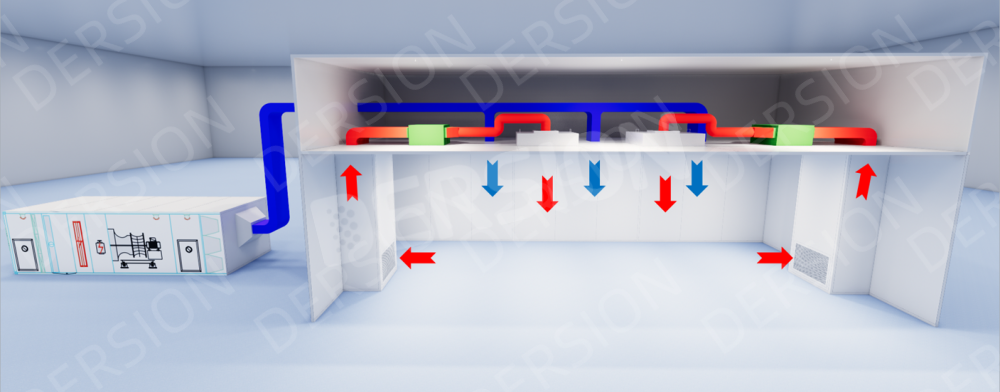

2. Space Layout and Airflow Organization

Airflow design is a decisive factor in maintaining cleanroom cleanliness and pressure control.

Depending on ceiling height, process sensitivity, and cleanliness class, common airflow patterns include:

-

Top supply & bottom return

-

Side supply & side return

-

Vertical unidirectional (laminar) airflow

High-grade cleanrooms (ISO Class 5 and above) typically require laminar airflow systems, often combined with FFU (Fan Filter Units) to achieve stable vertical unidirectional airflow.

Medium- and low-grade cleanrooms can use turbulent airflow systems, supported by HEPA or ULPA filters to meet cleanliness requirements.

When selecting air handling units (AHUs), sufficient mechanical room space must be reserved, as large modular AHUs can extend over ten meters in length. Alternatively, distributed FFU systems offer greater layout flexibility but require more advanced control systems.

3. Temperature, Humidity Control, and Energy Efficiency

Cleanrooms with strict environmental control requirements should be equipped with HVAC systems capable of:

-

Cooling and heating

-

Dehumidification and humidification

-

Precise automatic control

Using components such as motorized control valves, steam or electric humidifiers, and high-precision sensors, temperature fluctuations can be maintained within ±1°C, and humidity within ±5% RH.

For large-scale cleanroom projects, water-cooled chiller systems provide superior long-term energy efficiency. For small to medium cleanrooms, direct expansion (DX) air-cooled systems offer easier installation and maintenance.

Incorporating variable frequency drives (VFDs) further reduces energy consumption under partial load conditions. Redundancy designs, such as backup fans or standby units, are strongly recommended to ensure uninterrupted operation.

4. Maintenance Cost and System Reliability

Ease of maintenance is a key consideration in cleanroom HVAC selection. Systems should feature:

-

Easy-access filter replacement

-

Smooth internal surfaces for cleaning

-

Minimal downtime during maintenance

Selecting reputable HVAC brands and professional cleanroom engineering suppliers significantly reduces operational risk and ensures reliable after-sales support.

Conclusion

Cleanroom HVAC selection must always be driven by process requirements, supported by accurate load calculations and scientific airflow design. Only by choosing high-precision, high-reliability HVAC systems can cleanrooms achieve strict environmental control while maintaining energy-efficient and stable operation.

For best results, it is strongly recommended to work with an experienced cleanroom engineering company that provides integrated design, manufacturing, and installation services.

Post time: Dec-26-2025