Why does the perfection of a cleanroom depend on its supporting equipment? We can use an analogy: the building structure of a cleanroom is merely the "shell," while the supporting equipment is the "soul" that gives it life and enables it to truly function. Without this equipment, a cleanroom is no different from an expensive ordinary room.

However, in today's context of rapid technological development and increasingly stringent requirements for product quality and production environments, the construction of cleanrooms has become a crucial measure for many industries. Even a meticulously constructed cleanroom cannot function properly without the assistance of its supporting equipment.

First, the supporting equipment is the creator and guardian of the clean environment in a cleanroom. This is because the core value of a cleanroom lies in its controllable environmental parameters, including cleanliness, temperature and humidity, pressure differential, and airflow organization. These parameters are not automatically generated but rely on the precise operation of the supporting equipment.

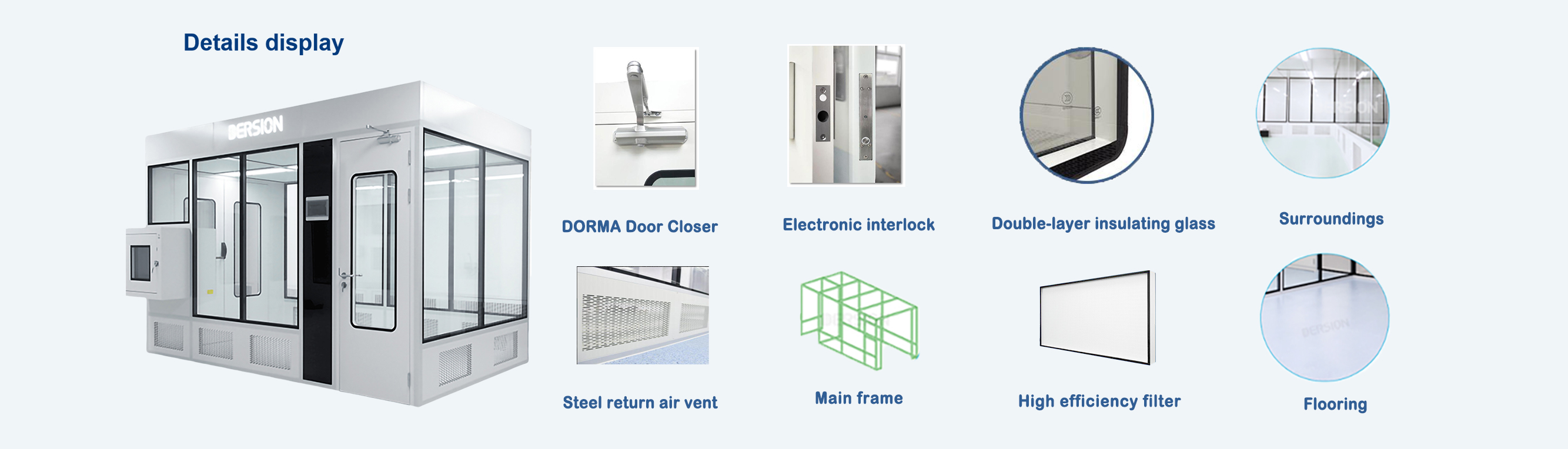

For example, the purification system within the cleanroom (including air conditioning units, dust removal units, HEPA filters, etc.) works collaboratively to process air, temperature, and humidity, continuously supplying and circulating clean air that meets standards, fundamentally creating a high-cleanliness environment. Other examples include air showers, pass-through windows, and buffer rooms, which act as guardians of the cleanroom environment.

Before entering the clean area, personnel and materials must pass through these devices for dust removal, effectively preventing contamination and maintaining the stability of the internal environment. Secondly, auxiliary equipment provides support and assurance for core processes. The purpose of building a cleanroom is to provide a reliable clean space for product manufacturing and research and development. In large cleanroom environments, some critical processes have even higher cleanliness requirements and require localized operations.

In this case, clean benches, biosafety cabinets, sterilization equipment, etc., play a crucial role, directly supporting and ensuring the feasibility and safety of highly complex critical processes.

Finally, supporting equipment also acts as a monitor and executor of the cleanroom system's stability. A sustainable cleanroom requires an intelligent and efficient system. It is typically equipped with sensors such as particle counters, temperature and humidity sensors, and differential pressure sensors. These sensors act like "eyes" and "sentinels," monitoring the cleanroom's environmental conditions in real time, issuing timely alarms and feedback, thereby helping the cleanroom operate stably and economically in the long term.

Therefore, cleanroom supporting equipment is not a dispensable "auxiliary role," but a "partner" as important as the building structure.

If a large sum of money is invested in building a cleanroom but the compatibility and reliability of the supporting equipment are neglected, then the cleanroom can only achieve its maximum effectiveness when these devices are running synchronously and efficiently

Post time: Dec-10-2025