ISO 13485 / GMP / FDA-Compliant Cleanroom Systems

End-to-end cleanroom design, manufacturing,and installation for medical device production and assembly.

- 1.ISO 14644 / ISO 13485 Compliant

-

2.Modular & Fast Deployment

-

3.Global Certifications: CE / UL / ISO

-

4.Designed for FDA & GMP Audits

Key Challenges in Medical Device Cleanroom Projects

Industry Expertise

We have deep experience in delivering ISO/GMP-compliant cleanrooms specifically for Class I–III medical devices.

→ We understand your regulatory challenges, and we build to match them.

Global Project Support

Whether in Asia, North America, or the Middle East, our team provides remote guidance or on-site support for cleanroom installation and training.

→ We’re ready wherever you are.

Turnkey Solutions

We provide end-to-end services: on-site measurement, custom design, engineering, production, trial assembly, shipping, and after-sales support.

→ One-stop service reduces coordination risks and accelerates project timelines.

In-House Manufacturing

Our cleanroom panels, doors, windows, and FFUs are all manufactured in our own ISO-certified facility, ensuring strict quality control, better lead time, and cost-efficiency.

→ You’re dealing directly with the source—no middlemen.

Precision Engineering & Modular Flexibility

Using our proprietary modular system, we deliver flexible and scalable cleanroom spaces that can be expanded, reconfigured, or relocated easily.

→ Future-proof your production environment.

Regulatory Compliance & Validation Support

We ensure compliance with ISO 14644, ISO 13485, FDA CFR 820, and GMP standards, and provide detailed documentation for audits and validation.

→ You get more than a room—you get peace of mind

Medical Device Industry Application Scenarios

Typical Products

- Syringes, infusion sets, blood collection tubes

- Catheters, drainage bags

- Medical masks and protective garments

Cleanroom Focus

- Particle and microbiological control

- High-volume, continuous production stability

Typical Cleanliness Level

- ISO Class 7–8

- Local critical zones: ISO Class 6

Key Cleanroom Areas

- Injection molding rooms

- Assembly and sealing areas

- Pre-sterilization buffer zones

Typical Products

- Orthopedic implants (plates, screws, joints)

- Cardiovascular stents and valves

- Dental implants

Cleanroom Focus

- Ultra-low particle levels

- Control of metal debris and surface contamination

Typical Cleanliness Level

- ISO Class 5–7 (depending on process)

Key Cleanroom Areas

- Post-machining cleaning rooms

- Surface treatment and coating areas

- Sterile packaging rooms

Typical Products

- Diagnostic reagent kits

- Test strips and cartridges

- Microfluidic chips

Cleanroom Focus

- Microbial contamination prevention

- Stable temperature and humidity control

- Batch-to-batch contamination avoidance

Typical Cleanliness Level

- ISO Class 7–8

- Local critical operations: ISO Class 6

Key Cleanroom Areas

- Reagent preparation rooms

- Filling and dispensing zones

- Drying and packaging areas

Typical Products

- Patient monitors and infusion pumps

- Ventilators

- Medical electronic modules

Cleanroom Focus

- Dust and ESD control

- Clean environment for electronic assembly

Typical Cleanliness Level

- ISO Class 7–8

Key Cleanroom Areas

- PCB assembly rooms

- Module assembly zones

- Functional testing and packaging areas

Typical Products

- Sterile surgical instruments

- Disposable sterile kits

- Sterile catheters and dressings

Cleanroom Focus

- High sterility assurance level (SAL)

- Integration with sterilization processes

Typical Cleanliness Level

- ISO Class 5–7

Key Cleanroom Areas

- Sterile assembly rooms

- Sterile packaging areas

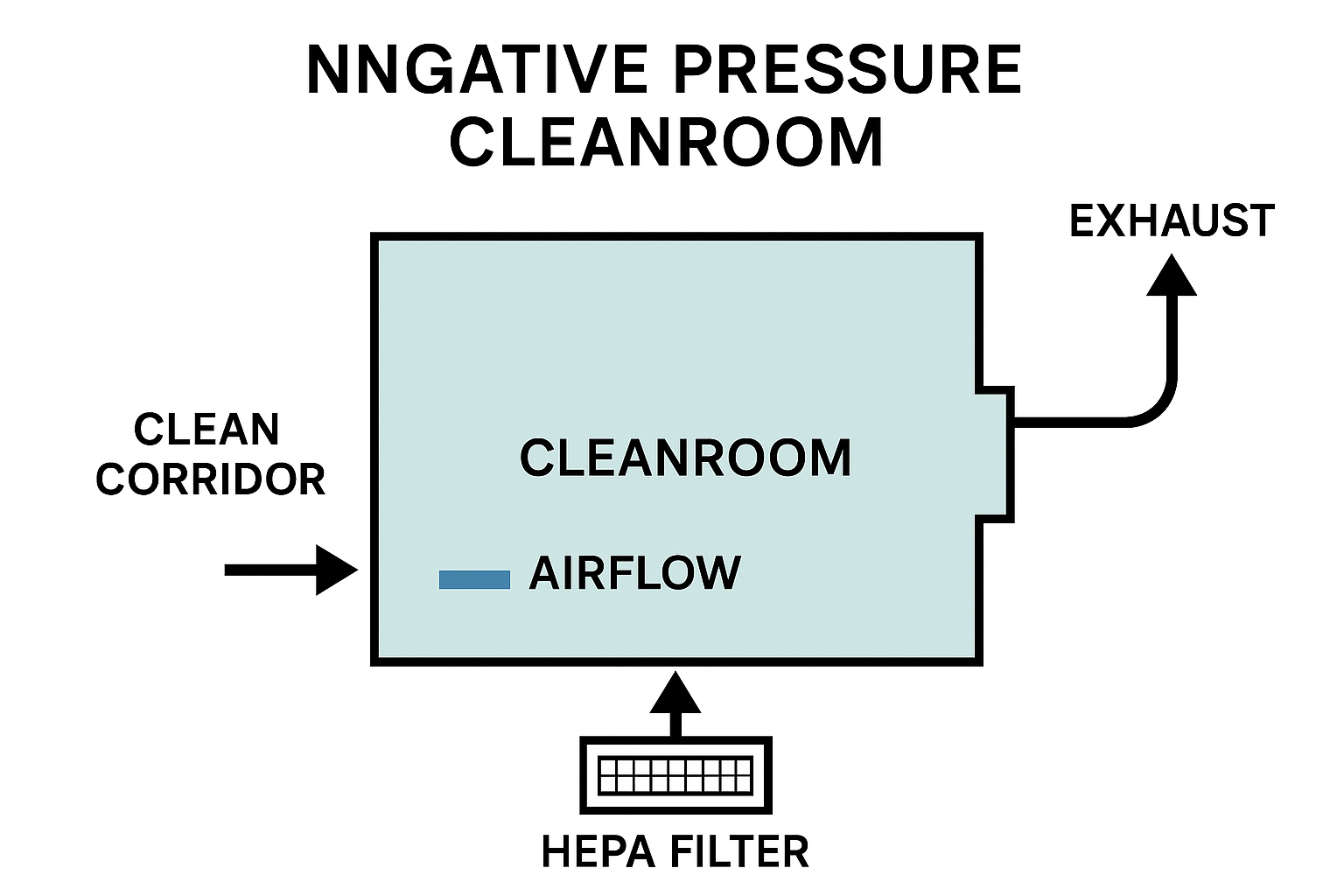

- Clearly defined pressure-controlled buffer zones

Application Scope

- Primary and secondary packaging

- Sterile barrier systems (Tyvek, blister packs)

Cleanroom Focus

- Prevention of secondary contamination

- Clear personnel and material flow

Typical Cleanliness Level

- ISO Class 7–8

Application Scope

- Product development and prototyping

- Process validation (IQ, OQ, PQ)

- Small-batch trial production

Cleanroom Focus

- High flexibility and modularity

- Fast deployment and easy reconfiguration

Typical Cleanliness Level

- ISO Class 6–8 (adjustable)

Cleanroom Design Built for Regulatory Approval

Applicable Processes

Medical Device Assembly & Aseptic/Non-aseptic Packaging &Injection Molding, Welding, Testing, Labeling

Modular Cleanroom System for Faster Deployment

Stable Temperature, Humidity & Cleanliness Control

Related Cases

Biological Industry Cleanroom——ISO5 70m²

Our biotech cleanroom solutions break through the traditional pharmaceutical cleanliness standards and are designed for cutting-edge fields such as cell and gene therapy, synthetic biology, and microbiome. The use of dynamic pressure gradient control systems and molecular-level air purification technology not only meets the ISO 14644-1 standard, but also achieves precise control of 0.1μm ultrafine particles.Through modular negative pressure isolation units and flexible space layout, we provide biotechnology companies with full-chain environmental protection from GLP laboratories to GMP production.

Pharmaceutical Industry Cleanroom——ISO7 30m²

Cleanroom design includes key control measures such as intelligent personnel/logistics diversion, air lock buffer system, dynamic environmental monitoring, etc., which are suitable for the production and packaging of sterile preparations, biopharmaceuticals, vaccines, injections and highly active drugs. Through full-cycle verification (DQ/IQ/OQ/PQ) and digital environmental monitoring systems, we provide pharmaceutical companies with a safe, reliable and compliant clean production environment, helping to improve drug quality and international market access.

Medical Devices Cleanroom——ISO7 146m²

This project strictly follows ISO 14644 and GMP standards to create a modern clean room that meets the cleanliness level of A/B/C/D. It adopts a high-efficiency HEPA filtration system, precise temperature and humidity control, and laminar airflow organization to ensure that air cleanliness, microbial limits, and environmental parameters continue to meet standards. The clean room design includes key measures such as personnel/logistics separation, strict dressing procedures, and real-time environmental monitoring, and is suitable for the production and packaging of high-demand products such as sterile medical devices, implants, and in vitro diagnostic reagents.

Start Your Cleanroom Project Today

Looking to build or upgrade a Medical Device cleanroom?

"Contact us for a free consultation!"